A Duo Wosintha: Makina Opindika Zitsulo za Hydraulic Ndi CNC Pressbrakes

Pamene mafakitale akupitilira kukula, kufunikira kwa makina apamwamba kwakhala kofunikira.Chimodzi mwazinthu zatsopano zomwe zikusintha makampani opanga zitsulo ndi kuphatikizamakina opindika zitsulo za hydraulicndi makina opindika a CNC.Zida ziwiri zamphamvuzi zimasinthiratu momwe chitsulo chimapindika, kumapereka kulondola, kuchita bwino komanso kusinthasintha kuposa kale.Mu positi iyi yabulogu, tiwona maubwino ndi mawonekedwe a awiriwa, ndikuwonetsa momwe angakhalire ofunikira pamakampani aliwonse opanga zinthu.

Mphamvu yamakina opindika zitsulo za Hydraulic:

Makina opindika achitsulo cha hydraulic ndi chida chosunthika chomwe chimapangidwira kuti chipinde ndikupanga mitundu yosiyanasiyana yazinthu, kuphatikiza chitsulo chachitsulo.Ndi mphamvu ya hydraulic, imagwiritsa ntchito mphamvu yayikulu pa chogwirira ntchito kuti chifike molunjika komanso movutikira.Kaya amagwiritsidwa ntchito m'mafakitale kapena malonda, makinawa amathandizira kwambiri kuwongolera komanso kuthamanga kwa njira yopindika mapepala.

CNC kupinda makina: chozizwitsa cha mwatsatanetsatane:

CNC pressbrakes, kumbali ina, tengani molondola ku mlingo watsopano.Makinawa amayendetsedwa ndi ukadaulo wowongolera manambala apakompyuta kuti apereke magwiridwe antchito opindika molondola komanso mosasinthasintha.Popanga ma angles enieni, kukula kwake ndi mawonekedwe mu makina, imatha kupanga mwachangu zida zambiri zofananira.Kulondola kumeneku kumachotsa zolakwika za anthu ndikuwonjezera mphamvu zonse pafakitale.

Kuphatikiza kwa hydraulic zitsulo kupinda makina ndi CNC kupinda makina:

Zida ziwiri zamphamvuzi zikaphatikizidwa, opanga adzawona kusintha kwakukulu kwa zokolola, zabwino ndi zotsika mtengo.Kuphatikiza kwa makina opindika zitsulo za hydraulic ndi CNC pressbrakes amalola opanga zitsulo kuti akwaniritse mapindikidwe ovuta kwambiri ndikusunga nthawi ndi khama.

Pangani bwino ndikupulumutsa nthawi:

Kuphatikizika kwa kuthekera kwa CNC mu makina opindika zitsulo za hydraulic kumatha kukulitsa makina opangira.Ntchito zopindika zitha kupangidwa zokha pokonza miyeso ndi ma angles ofunikira mu dongosolo la CNC.Izi sizimangochepetsa ntchito yofunikira komanso zimafulumizitsa nthawi yonse yopanga.Ntchito yowononga nthawi yoyesera pamanja, kuwerengera ndi kusintha ma angles tsopano ndi yakale.

Kusinthasintha ndi kusinthasintha:

Ubwino wina waukulu wa awiriwa ndi kusinthasintha kwawo.Kuphatikiza ma hydraulic metal press brakes ndi CNC press mabuleki amalola opanga kupindika zinthu zosiyanasiyana, kuphatikizapo chitsulo chosapanga dzimbiri, aluminiyamu ndi chitsulo cha carbon, mosavuta komanso molondola.Kusinthasintha kumeneku kumathandiza opanga zitsulo kuti akwaniritse zosowa za mafakitale osiyanasiyana, kuchokera ku magalimoto ndi ndege kupita ku zomangamanga ndi zamagetsi.

Kulondola kwapadera komanso kusasinthika:

Kuphatikiza apo, kuphatikiza kwaukadaulo wa CNC kumatsimikizira kulondola komanso kusasinthika pamapindi onse.Pochotsa zolakwa za anthu ndi kusagwirizana, opanga angapereke mankhwala abwino kwa makasitomala.Dongosolo la CNC limawonetsetsa kuti kupindika kulikonse kumachitidwa molondola kwambiri, zomwe zimapangitsa kuti pakhale kusasinthika mu batch yonse.

Pomaliza:

Mwachidule, kuphatikiza makina opindika zitsulo za hydraulic ndi makina opinda a CNC asintha makampani opanga zitsulo.Kuchulukirachulukira, kuchita bwino komanso kusinthasintha koperekedwa ndi kuphatikizaku kumakweza mipiringidzo yopindika mapepala.Makampani opanga padziko lonse lapansi tsopano atha kuwonjezera zokolola, kuchepetsa ndalama ndikuwonjezera kukhutira kwamakasitomala.Pamene ukadaulo ukupitilirabe kusinthika, ndizosangalatsa kuganiziranso zamtsogolo zamakina odabwitsawa, ndikutsegulira njira ya tsogolo labwino pakupanga zitsulo.

Mawonekedwe

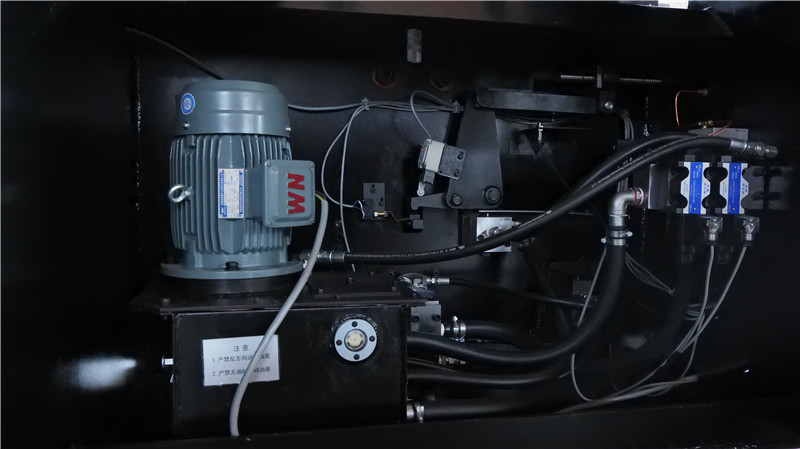

Kugwiritsa Ntchito Pansi Pamwamba Kumathandiza Kusintha Kwachidule Kwa Zida Zazikulu Zazikulu.chida cha Dr/ve Chimabisika Pansi Pagawo Lalikulu Lazida Zazida, Zomwe Zimasunga Malo Pakati Pamafelemu, Ndipo Imatha Kukonza Zida Zazikulu Zazikulu.

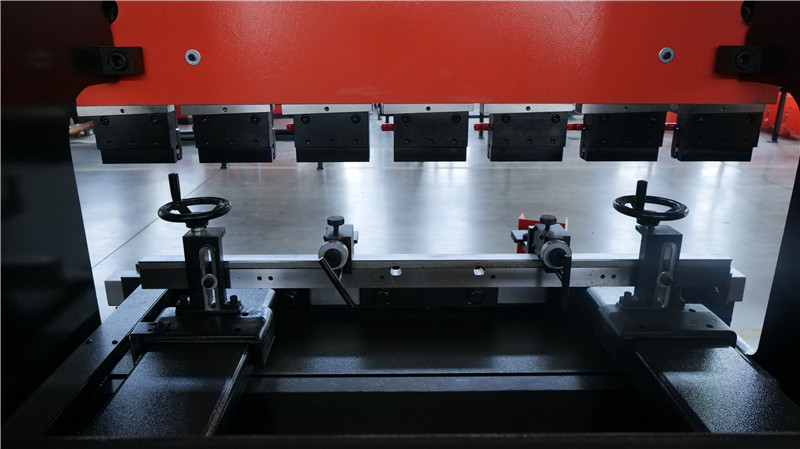

• Kugwiritsa Ntchito Kupanikizika Kwapakati Kupewa Mphamvu Yosakwanira Pakati Pa Ntchito Yogwirira Ntchito

Kukumana ndi Njira/ng Yazinthu zolondola kwambiri.

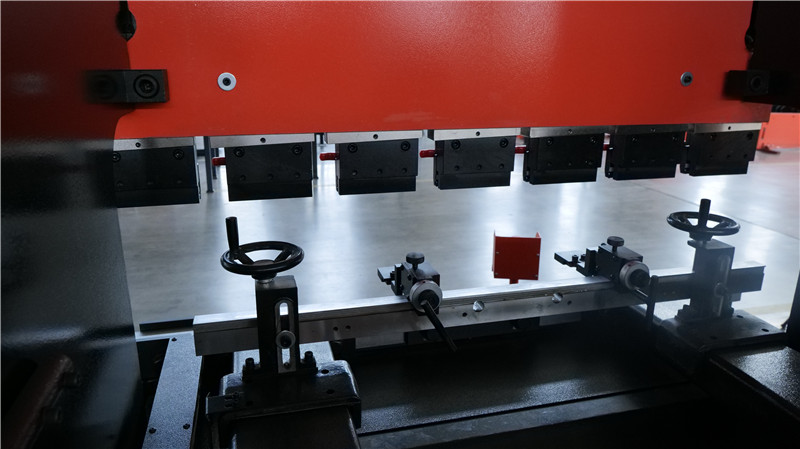

• Panthawi Yokonza, The Worktable Ndi Yokhazikika Ndipo Sidzasuntha.Buku Lodzigudubuza

Mechanism Imakonzedwa Kutsogolo, Kumbuyo, Kumanzere Ndi Kumanja Kwa Kumunsi

Worktable, Zomwe Zingapangitse Kuti Ntchito Yogwira Ntchito Isunthike Momasuka, Ndipo Imatha Kusintha Mosavuta

Kusiyana Pakati pa Ma Rollers Ndi Ma block blocks, Kuti Muchepetse Kuvala Kwaupangiri Wantchito.

• Mapangidwe Abwino Apangidwe Apangidwe Amasunga Zofunikira Zapamwamba Ngakhale Pambuyo Kugwiritsidwa Ntchito Kwa Nthawi Yaitali.The Upper Worktable Imatengera Njira Yokonzera Oblique Block

Pewani Kusokonekera Ndi D / chisokonezo mu Welding Frame ndikuwonetsetsa Kulondola kwa Kugwiritsa Ntchito Nthawi Yaitali.Kusintha kwa Micro-elastic Kwa Frame Panthawi Yokonza Can

Khazikitsani Bwino Patsogolo pa Benchi Yogwirira Ntchito.

• Malire Otsikirapo Pos/tion Ya Pansi Pansi Amakhazikitsidwa Powerenga Encoder Pos/tion.

Mu Des/gn iyi, Malire Otsika Osiyanasiyana Atha Kukhazikitsidwa Molingana ndi Bend Yosiyana-

Utali Wautali, Potero Kupititsa patsogolo Kuchita Bwino Kwa Kupindika.

• Idapangidwa Ndi Ntchito Yopindika Mwapang'onopang'ono ya Arc, Ndipo Gauge Yakumbuyo Imapita Patsogolo- Ward Pa Mipata Yofanana.Nthawi iliyonse Imasuntha, Bend Imodzi Imapangidwa, Ndipo Radian Yofunidwa Ndi Mbali Yophatikizidwa Imapangidwa Pambuyo Nthawi Zambiri Zakupindika.

• Ntchito Yopewera Kubwerera Kumbuyo, Mwa Kukhazikitsa Pos/tion Kumbuyo-Kukokera Ndi Kuchedwa Kukokera Kumbuyo, Ntchito Yogwirira Ntchito Itha Kupewedwa Kutsutsana Ndi Kuyimitsa Kumbuyo Panthawi

Njira Yopangira Machining The Workpiece.

• Ntchito Yowerengera Nambala Yonse Ya Zigawo Zopindika.

Mquick Splint Ndi Yosavuta Kugwiritsa Ntchito Ndipo Yafunsira Patent.

• Makina Opindika Pansi Pansi Akukwera Ndi Kupindika, Galimoto Imayendetsa Pampu Ya Gear Kuti Itulutse Mphamvu, Ndipo Ikamatsika Ndi Kubwerera, Imazindikirika Ndi Kulemera Kwa The Worktable / Payokha, Ndipo Idling Yamoto Imapulumutsa Mphamvu.

• Wy-100 Imatengera Mapangidwe Ozungulira Mafuta a Silinda Ya Mafuta Amodzi Ndi Ma Cylinder Awiri Othandizira Othandizira, Omwe Angakhale Yeniyeni / Zeni Zomwe Zimagwira Ntchito Pansi Pansi, Kutulutsa Ndikofanana, Ndipo Chogwirira Ntchito Sichimawonongeka Mosavuta.

tsatanetsatane wazinthu

| Chitsanzo ndi zokhudzana kasinthidwe | ||

| Mode | WY-100 | WY-35 |

| CNC ndondomeko | Hollysy5 | Hollysys |

| Servo system | Panasonic/Fuj | Panasonic/Fuj |

| Servo moto | Pangsonic / Fuj | panasonic/Fuj |

| Mphamvu (KN) | 1000 | 350 |

| Utali wopindika(mm) | 3000 | 1400 |

| Kukwapula mmwamba (mm) | 100 | 100 |

| Kuzama kwa mmero(mm) | 405 | 300 |

| No.Cylinder | 3 (1 mgin.2 Wothandizira) | 1 |

| Kuthamanga kwachangu (mm/sekondi) | 58 | 46 |

| Liwiro lopindika (mm/mphindikati) | 10.8 | 8 |

| Liwiro loyandikira (mm/sekondi) | 52 | 40 |

| Kumtunda ndi kumunsi kwa baffle (mm) | 55-140 | 55-140 |

| Mphamvu yololeka ya baffle(N) | 100 | 100 |

| Kuyika kwa backgauge mwatsatanetsatane (mm) | ±0.1 | ±0.1 |

| X axis stroke (mm) | 430 | 430 |

| X-axis max.Liwiro lakudya (mm/mphindi) | 15 | 15 |

| X-axis repositioning kulondola (mm) | ± 0.02 | ± 0.02 |

| Mphamvu yamagalimoto (KW) | 5.5 | 2.2 |

| Kulemera (kg | 6700 | 2200 |

| Kuchuluka kwa thanki yamafuta (L) | 65 | 30 |

chiwonetsero chatsatanetsatane