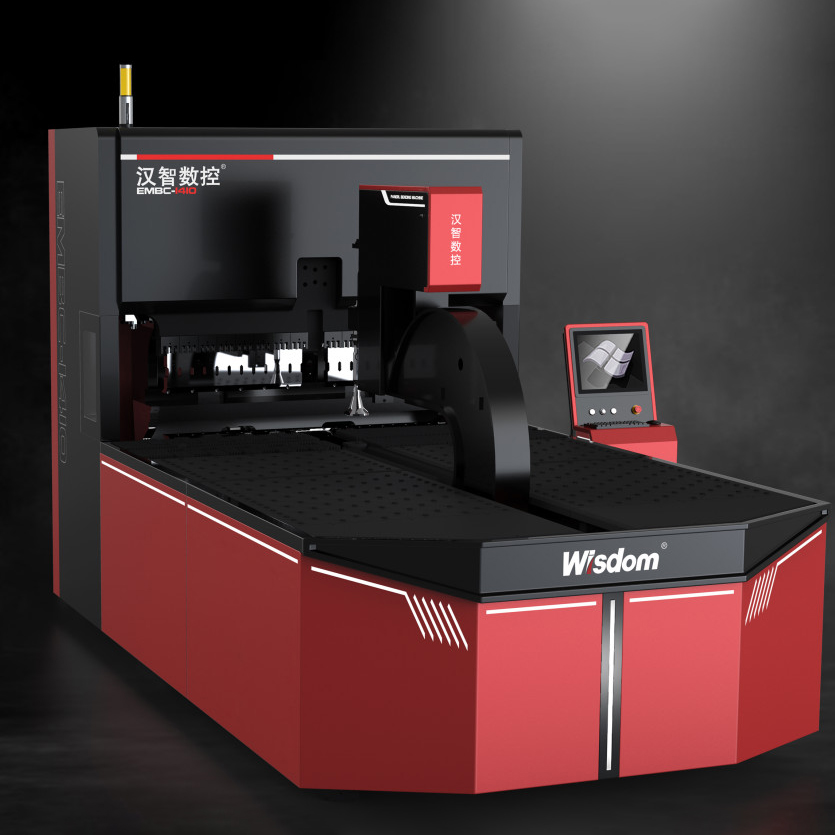

Laser Welding Machine Yonyamula Pamanja Fiber Laser Welder Makina a Zitsulo

Kanema

Kugwiritsa ntchito

Kuwotcherera kwa laser ndi mtundu wa kuwotcherera komwe kumagwiritsa ntchito laser kusungunula zinthu zomwe zikuphatikizidwa.Imagwira ntchito m'mafakitale ambiri, monga zamagalimoto, zakuthambo, komanso kupanga zida zamankhwala.Kuwotcherera kwa laser kungagwiritsidwe ntchito kujowina zida zovuta kuziwotcherera, kuphatikiza aluminium ndi zitsulo zosapanga dzimbiri.Zimapanganso ma welds olondola kwambiri kuposa njira zamawotchi chifukwa chakulondola kwake komanso kulondola.

laser kuwotcherera makina Kusamala ntchito

1. Valani zovala zodzitchinjiriza, magolovesi ndi magalasi mukamagwiritsa ntchito makina owotcherera a laser.2. Chonde tsimikizirani kuti mbali zonse za makinawo zimasungidwa bwino komanso zili bwino musanagwiritse ntchito.3. Onetsetsani kuti malo ogwirira ntchito ali ndi mpweya wabwino kuti ateteze kudzikundikira kwa zinthu zoopsa chifukwa cha ntchito zowotcherera.4. Panthawi yogwiritsira ntchito makina opangira laser, chonde tcherani khutu ku zoopsa zomwe zingatheke monga moto, utsi kapena zopsereza.5. Yang'anani zolumikiza zotayirira kapena mawaya osokonekera musanagwiritse ntchito, ndipo samalani ngati kuli kofunikira kuti mupewe ngozi yamagetsi yokhudzana ndi magetsi a makinawo kapena zigawo zake zamkati / mabwalo.6. Pochita ntchito zowotcherera laser pazitsulo monga zitsulo ndi aluminiyamu, mtunda wotetezeka uyenera kusungidwa kuzinthu zoyaka moto monga mapepala ndi pulasitiki, zomwe zimatha kuyaka pansi pazifukwa zina.7. Osawotcha zinthuzo pothamanga ma pulses omwe ndi aatali kwambiri, izi zimatha kusokoneza gawo la welded kapena kuwononga madera ozungulira.8. Samalani kutaya zidutswa zotentha zomwe zimatuluka pambuyo pa ndondomeko ya soldering.

chiwonetsero chatsatanetsatane