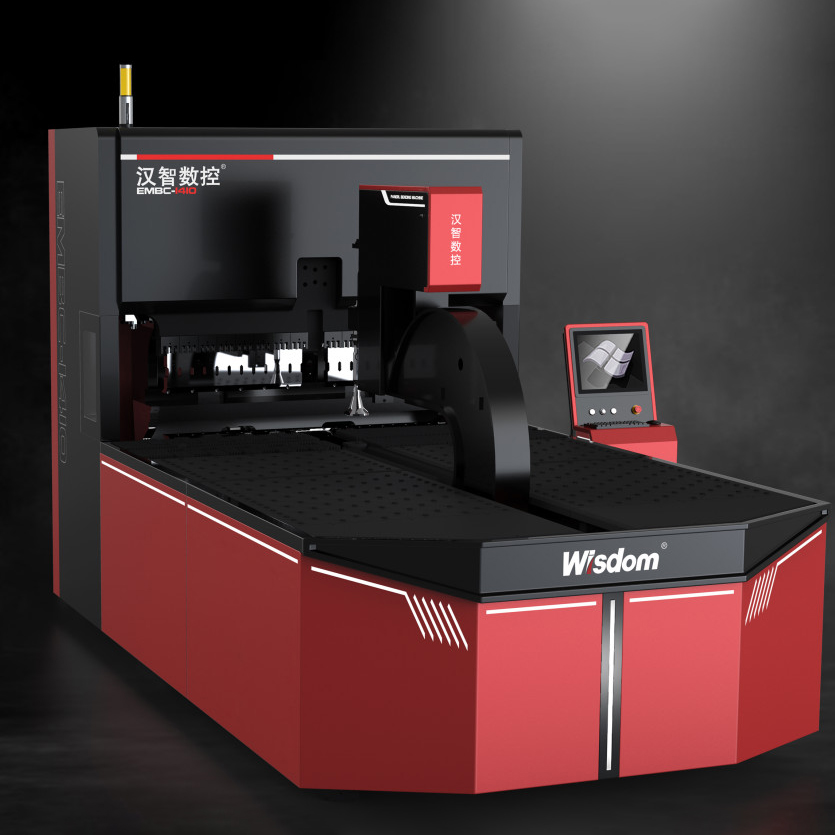

Semi-automatic Panel Bender EMBC 1402

tsatanetsatane wazinthu

| Ayi. | Dzina | Parameter | Chigawo |

| 1 | Max.utali | 1400 | mm |

| 2 | Max.width | 1400 | mm |

| 3 | Min.Utali wopindika | 200 | mm |

| 4 | Min.kupindika m'lifupi | 260 | mm |

| 5 | Makulidwe a Max.bending (MS,UTS410N/mm²) | 1 | mm |

| 6 | Min.bending makulidwe (MS, UTS410N/mm²) | 0.5 | mm |

| 7 | Max.kupindika kutalika | 170 | mm |

| 8 | Utali wosinthitsa mawonekedwe a upper press Manual | ||

| 9 | Avereji yogwiritsa ntchito mphamvu | 2.2 | KW |

| 10 | Kulemera | 15 | T |

Makhalidwe ndi kapangidwe kake

Pankhani yopanga makina ndi kupanga, Hebei Hanzhi CNC Machinery Co., Ltd.imayang'ana kwambiri mfundo zotsatirazi:

1. Lingaliro lazamalonda lomwe limatsata zothandiza ndikusunga wosuta ndalama iliyonse.

2. Lingaliro lodalirika kwambiri komanso lolondola la mapangidwe.

3. Zida zapamwamba kwambiri, zida zogulidwa ndi njira zabwino zopangira.

4. Kugogomezera kwambiri kumasuka kwa ntchito ndi kukonza ndi chitetezo.

5. Mtengo wochepa wokonza ndi kukonzanso mtengo mumakampani omwewo.

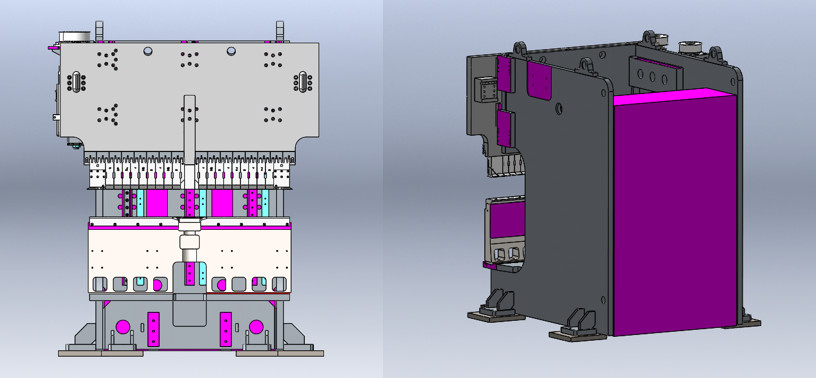

chimango

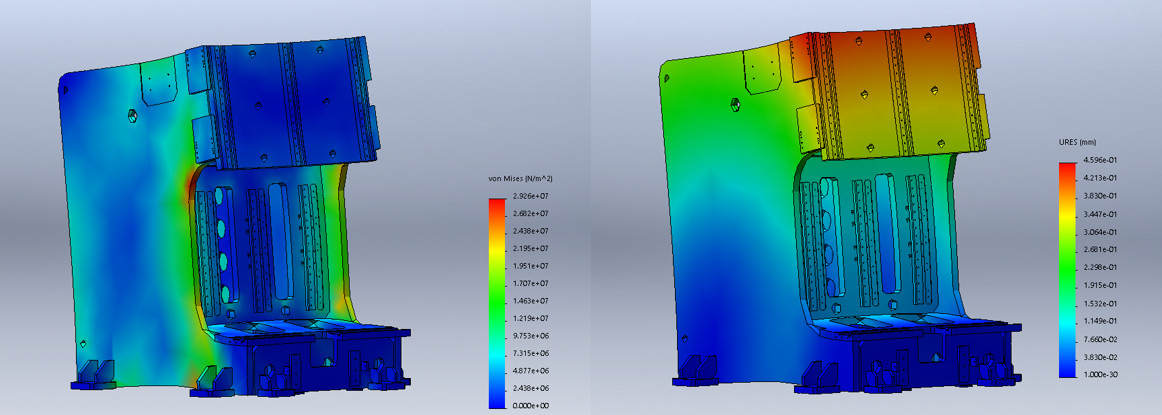

A. Kupanga 3D finite model model: Kutengera ndi 3D solid model yopangidwa ndi yopangidwa, 3D finite model model imapangidwa kuti isawerengedwe.Chitsanzocho chimayang'ana zigawo zazikulu pa mgwirizano wotumizira mphamvu.Mphamvu zimasamutsidwa ku chotengera kudzera mu kugwirizana ndiyeno kusanthula mphamvu za kubereka kumachitika.

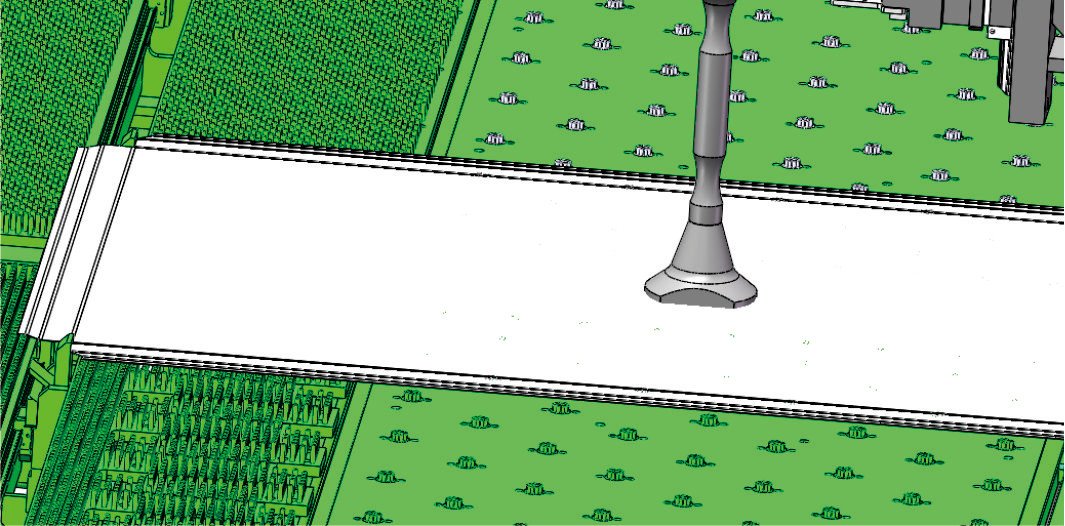

Chithunzi cha 1 Panel bender Finite element yosinthira makina athunthu

B. Kusanthula kwa Zotsatira za Static Analysis: Chifukwa cha liwiro la makina ofulumira, kusanthula kwa mphamvu kumatha kuchepetsedwa kukhala vuto lokhazikika.Kutengera ndi katundu woponderezedwa wa mbale ndi kupindika kolowera molunjika kwa mutu wodulira, kupsinjika ndi zotsatira zopindika zikuwonetsedwa pansipa.The pazipita kupsyinjika limapezeka pakhosi pa thupi ndi maganizo pazipita 21.2mpa ndi mapindikidwe pazipita limapezeka kumtunda mapeto a thupi ndi mapindikidwe pazipita 0,30mm.

Malinga ndi zotsatira za kusanthula kwachindunji kwa chimango, chitsulo cha Q345 chinasankhidwa kukhala chinthu;kuwotcherera chishango cha carbon dioxide kunatengedwa;kutenthetsa mankhwala kunachitika kuti athetse mavuto omwe amapangidwa ndi kuwotcherera;motero kuonetsetsa kulondola, kukhazikika komanso kukhazikika kwakukulu kwa zida zogwirira ntchito nthawi yayitali.

Mkuyu 2 kupsinjika maganizo kusamuka kusinthika kusanthula zotsatira za chimango

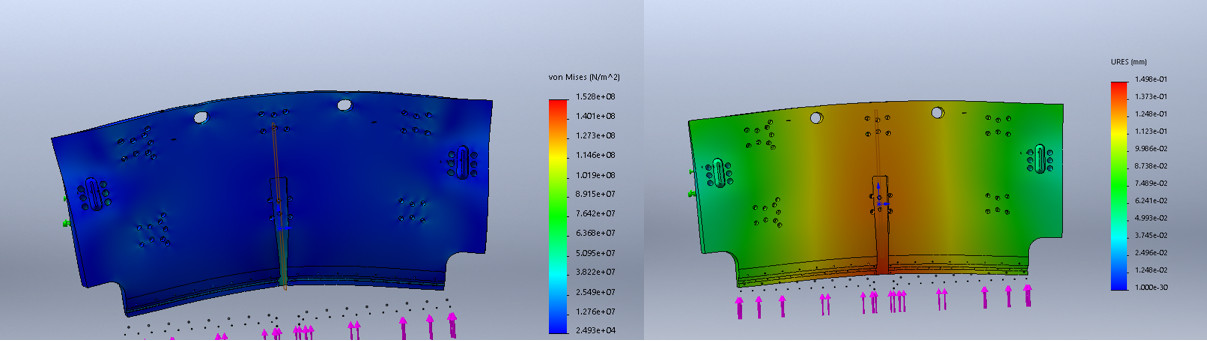

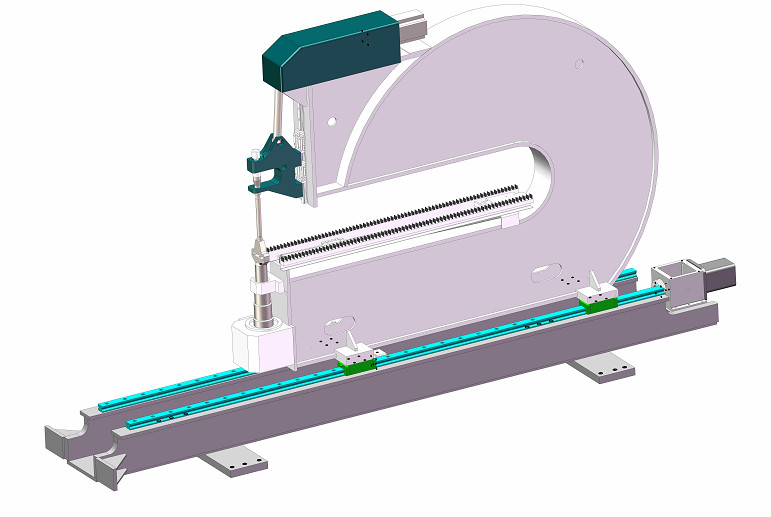

Nkhosa ya pamwamba

Gawoli makamaka limapangidwa ndi slider, torque lead screw, chochepetsera, njanji yowongolera, mota ya servo ndi zina zotero.Kuyendetsa kwakukulu kumayendetsedwa ndi servo motor ndipo njira yoyendetsera ndi servo synchronous control, yomwe imatha kutsimikizira kulondola kwa malo, kuthamanga komanso kuwongolera kwakukulu.Kupaka mafuta kwa wononga wononga ndi njanji yowongolera kumatenga kudzoza kodziwikiratu, ndipo mafutawo ndi 00 #, omwe amatsimikizira moyo wautumiki ndi kulondola kwa wononga zotsogola ndi njanji yowongolera kwa nthawi yayitali.

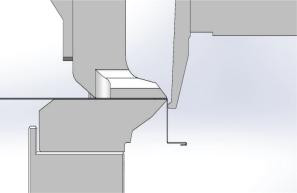

Kusanthula kosasunthika kwa chotsitsa cham'mwamba: chithunzi chapamwamba cha kupsinjika kwa impso chapamwamba chikuwonetsa kuti kupsinjika kwakukulu kumawonekera kumtunda, kupsinjika kwakukulu ndi 152mpa, kupindika kwakukulu kumawonekera kumapeto kwa gome lakumtunda, kupindika kwakukulu. ndi 0.15mm

Mkuyu 3 zotsatira za kusuntha kwa nkhawa za nkhosa yamphongo

Malinga ndi zotsatira zowunikira zowunikira za nkhosa yamphongo, chitsulo cha Q345 chinasankhidwa kukhala chinthu;Kuwotcherera kotetezedwa kwa CO2 kunagwiritsidwa ntchito;tempering mankhwala unachitikira kuthetsa nkhawa chifukwa kuwotcherera;motero kuonetsetsa kulondola, kukhazikika komanso kukhazikika kwakukulu kwa zida zogwirira ntchito nthawi yayitali.

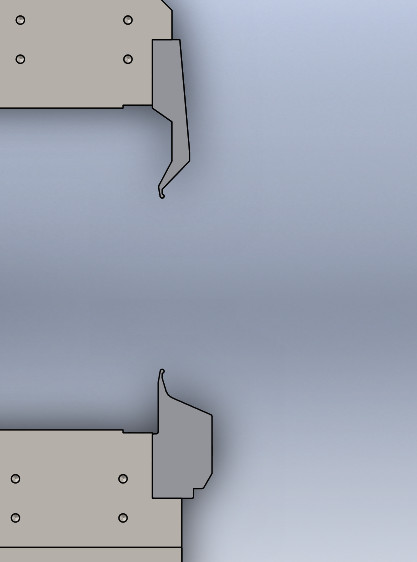

Kupindika unit

Mphamvu yoyendetsa gawo lagawo lopindika imayendetsedwa ndi mota ya servo popanda kuphatikizidwa ndi ma hydraulic system, omwe ali ndi zabwino zambiri pochepetsa kuwonongeka kwa zigawo ndi kufalikira kwamphamvu, mogwirizana ndi kupulumutsa mphamvu ndi chitetezo cha chilengedwe chomwe chimalimbikitsidwa. ndi boma.

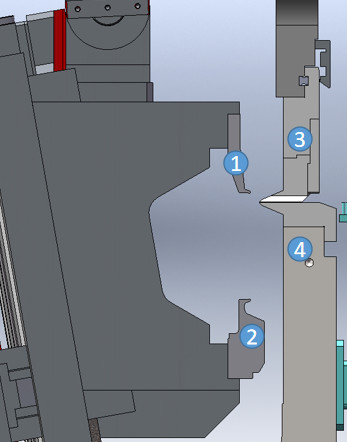

Malinga ndi kukhazikitsidwa kwa chidziwitso cha pepala, makinawo amawerengera malo a mpeni wapamwamba kwambiri 3 ndikuwongolera mtunda pakati pa mpeni wapamwamba 3 ndi mpeni wapansi 4 kukonza pepala;molingana ndi kakhazikitsidwe kachitidwe, kaya kupindika uku kuli m'mwamba kapena pansi, mpeni wotsitsa wapansi 2 kapena mpeni wapamwamba kwambiri 1 umayendetsedwa kuti usunthe mwachangu kumalo opindika;molingana ndi ma angles osiyanasiyana, mpeni wopindika umawongoleredwa kuti usamukire kumalo owerengeka kudzera mu formula yowerengera yovomerezeka kuti mumalize kupindika.

Malingana ndi njira zosiyanasiyana zopindika, zikhoza kugawidwa kukhala kupindika kwa ngodya, kupindika kwakukulu kwa arc, kupindika kwa flattening, etc., komwe kupindika kumagawidwa kukhala kupindika mmwamba ndi pansi.

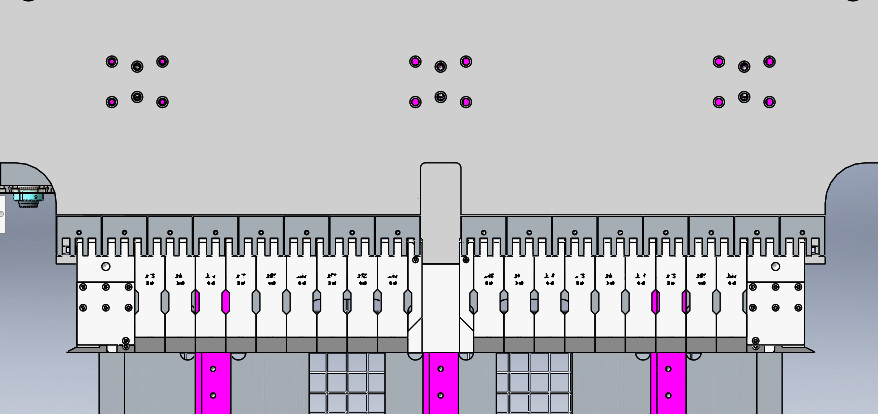

Chigawo chapamwamba chosindikizira

Fig.6 Upper press unit

Chigawo chapamwamba chosindikizira: gawo la njira zonse zopindika, EmbC full servo multilateral kupinda pakati ili ndi makina apadera apamwamba omwe amatha kukhazikitsidwa ndi kusinthidwa pamanja kwa utali wosiyana wa mbale.

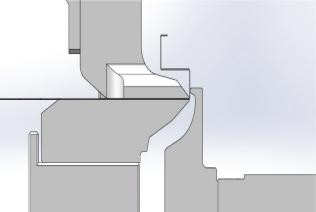

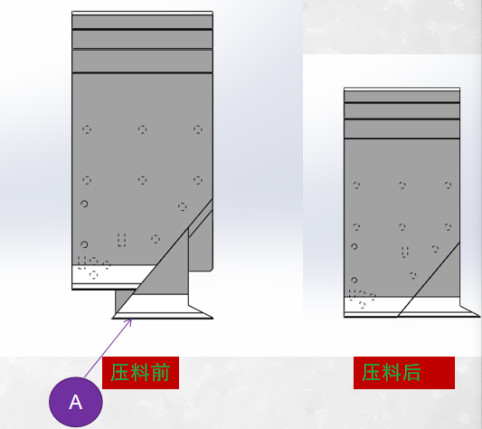

Kuti tikwaniritse zofunikira za bokosi lopindika, tapanga njira yapadera yopewera.Musanayambe kukanikiza, gawo la kupewa kufa lili m'boma lisanayambe kukanikiza pazithunzi ndikuyamba kudyetsa.Pambuyo pa kudyetsa, ili m'boma mutatha kukanikiza pazithunzi ndikuyamba kupinda.Pambuyo kupindika, chowongolera chapamwamba chimasuntha.Pakusuntha kwa slider yakumtunda, gawo A limangosunthira ku boma musanakanikize.Pambuyo slider chapamwamba chasunthira kumalo okhazikitsidwa, kusuntha kotsatira kumayamba.

Fig.7 Kupewa kwa bokosi

Chida

Zida zopindirira zimagawidwa m'zida zopindirira chapamwamba ndi zida zopindira pansi.Zida zopindika zapadera zimatha kusinthidwa malinga ndi zofunikira zosiyanasiyana za kasitomala.

2.Chigawo chodyetsera mbale:

Kusuntha, kugwedeza ndi kuzungulira kwa pepala zitsulo kumayendetsedwa ndi robot 1, fixture 2 ndi disc yozungulira 3 motsatira.Panthawi yonse yopangira makina, kudyetsa zitsulo zachitsulo kumayendetsedwa ndi ma servo motors, kupangitsa kuti ziziyenda zokha komanso kuziyika mwachangu, kuchepetsa nthawi zoyenda ndikuwonjezera mphamvu.Chifukwa cha mapangidwe apangidwe komanso kugwiritsa ntchito mphamvu zonse za servo, kugwedeza ndi kuzungulira kwa chitsulo chachitsulo kumatha kusunga zolondola panthawi yonse yogwira ntchito ya multilateral kupinda pakati.Pazinthu zambiri zovuta, ngakhale za polygonal, kusinthasintha kosalekeza kwa 0.001 kumatha kutsimikizika.

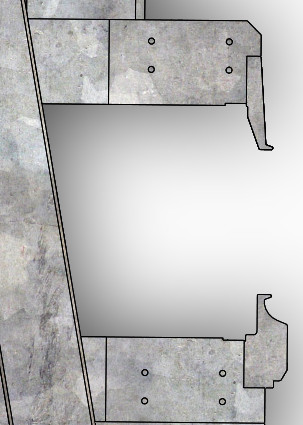

3. Plate Positioning Unit:

Pini yoyika mbale imakhala ndi pini yoyika kumanzere, pini yoyika kumanja, pini yoyika kutsogolo ndi pini yakumbuyo;zikhomo kumanzere ndi kumanja kuyika mbale kumanzere ndi kumanja.Pini yakutsogolo ndi pini yakumbuyo imawongolera kutsogolo ndi kumbuyo kwa mbale ndikuwonetsetsa kuti mbaleyo ikufanana ndi mipeni yosindikizira yapamwamba komanso yotsika, yomwe imagwiritsidwa ntchito kuwonetsetsa kuti mbaleyo ili yolondola.

The mbale udindo wagawo akhoza basi kuyika mbale ndi basi kumaliza multilateral kupinda pa nthawi imodzi, amene amafupikitsa kwambiri kupinda mkombero nthawi, amazilamulira kumeta ubweya cholakwa cha mbale poyamba kupinda ndi kuonetsetsa kulondola kwa kupinda.

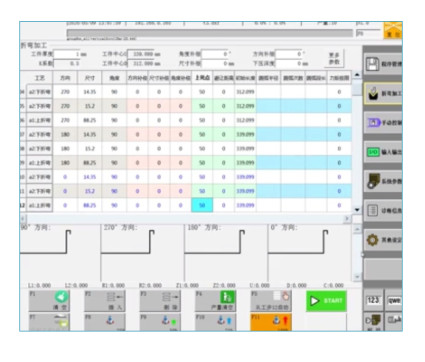

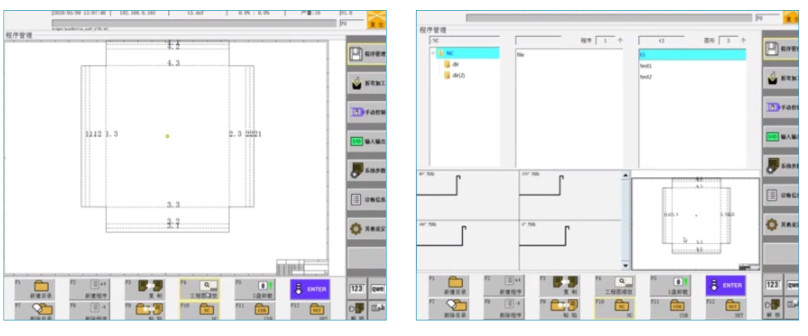

4.CNC dongosolo

A: Pamodzi opangidwa CNC machitidwe ndi mapulogalamu angagwiritsidwe ntchito ndi kusamalidwa mwamsanga ndi mosavuta

B: Zofunikira.

a) .Njira yowongolera mabasi ya EtherCAT yokhala ndi kusokoneza kwakukulu

b) Imathandizira pulogalamu yachindunji, kupindika deta pagawo lililonse kumatha kulowetsedwa mu mawonekedwe

c) Kuthandizira kupindika kopindika

d) Kuwongolera kwathunthu kwamagetsi a servo

e) Thandizo la chipukuta misozi

f) Kuthandizira mapulogalamu amitundu iwiri

2D mapulogalamu ntchito, kuitanitsa 2D DXF kujambula deta, basi kupanga mapindikidwe, kukula kupinda, kupinda ngodya, kasinthasintha ngodya ndi deta zina.Pambuyo kutsimikizira, basi kupinda processing akhoza kuchitidwa

Mndandanda wa gawo lalikulu

| Ayi. | Dzina | Mtundu |

| 1 | Chimango | Nzeru |

| 2 | Chida | Nzeru |

| 3 | Kupindika unit | Nzeru |

| 4 | CNC System | Nzeru |

| 5 | Servo motere | Nzeru |

| 6 | Woyendetsa wa Servo | Nzeru |

| 7 | Sitima | Nzeru |

| 8 | Mpira | Nzeru |

| 9 | Wochepetsera | Taiwan |

| 10 | Wophwanya | Schneider |

| 11 | Batani | Schneider |

| 12 | Gawo lamagetsi | Schneider |

| 13 | Chingwe | Yicu |

| 14 | Kusintha kwapafupi | Omuroni |

| 15 | Kubereka | SKF/NSK/NAICH |

4) Kupanga, kupanga, kuyang'anira ndi kukhazikitsa chida cha makina kumakwaniritsa izi.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Zida zotsalira ndi mndandanda wa zida

| Ayi. | Dzina | Qt. | Ndemanga |

| 1 | Bokosi la zida | 1 | |

| 2 | Ikani pad | 8 | |

| 3 | Impanda wa hexagon | 1 seti | |

| 4 | Mfuti yowonjezera mafuta pamanja | 1 | |

| 5 | Buku la CNC system | 1 | |

| 6 | chotsegula sipana | 1 |